I. Overview

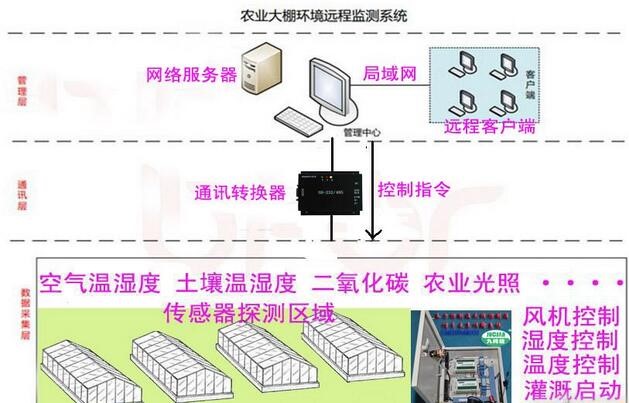

The agricultural greenhouse intelligent greenhouse monitoring system collects the air temperature, humidity, light, soil temperature, soil moisture and other environmental parameters in the agricultural greenhouse in real time, makes real-time intelligent decision-making according to the needs of crop growth, and automatically turns on or off the designated environmental adjustment equipment. Through the deployment and implementation of the system, it can provide scientific basis and effective means for automatic monitoring of agricultural ecological information, automatic control of facilities and intelligent management.

The greenhouse monitoring and intelligent control solution is through various wireless sensors and network transmission equipment that can be flexibly deployed in the greenhouse to monitor the temperature, humidity, light, soil temperature, soil moisture content, CO2 concentration, etc. Real-time collection of relevant environmental parameters, storage and intelligent analysis and decision-making of real-time monitoring data on the data server, and automatic opening or closing of designated equipment, such as remote control of irrigation.

With the wide application of agricultural production technologies such as greenhouse planting, factory seedling raising and facility cultivation, rapid and accurate collection and analysis of environmental parameters has become a realistic demand. If the parameters are collected, on the one hand, the environmental parameters of crop growth can be known in time, and on the other hand, the adjustment of the greenhouse environment can be controlled according to the collected parameters to provide a suitable growth environment for the growth of crops. Since the environmental conditions such as humidity and temperature in the greenhouse are not suitable for the work of ordinary PC computers, a single-chip microcomputer is used for data acquisition, and the collected data can be transmitted to the upper PC computer through the serial port transmitting and receiving equipment for analysis and processing.

Room control system is an environmental automatic control system specially developed and produced for agricultural greenhouse, agricultural environment control and meteorological observation. It can measure the environmental temperature, environmental humidity, light intensity, soil temperature, soil moisture, carbon dioxide concentration and other agricultural environmental factors in the greenhouse. Irrigation and fertilization and other environmental control equipment can automatically adjust the environment in the greenhouse to reach the range suitable for plant growth and provide a better environment for plant growth. The intelligent greenhouse control system can make the greenhouse run in an economical and energy-saving state, realize the unattended automatic operation of the greenhouse, reduce the labor intensity of personnel, and reduce the energy consumption and operation cost of the greenhouse.

The energy control system can automatically control the automatic actions of the solenoid valve, water pump, fertilization system, etc. according to the parameters of the soil humidity sensor, soil temperature sensor, time and so on in the greenhouse. Carbon dioxide sensor, rain and snow sensor and other parameters to automatically control the automatic actions of skylights, side windows, inner shading, outer shading, fans, wet curtains, eversion windows, heating equipment, humidification equipment, carbon dioxide generators, etc. The environment remains within user settings.

Second, customer needs

(1) Intelligent greenhouse control system

With the rapid development of the national economy, modern agriculture has made great progress. Solar greenhouses, plastic greenhouses, etc. have been widely built throughout the country according to needs, creating a good growth environment for crops. Greenhouse engineering has become an important part of efficient agriculture.

Shed is to establish a simulation of climatic conditions suitable for biological growth and create an artificial meteorological environment to eliminate the restrictions on biological growth such as temperature and humidity. It can enable different crops to be produced in unsuitable seasons, and partially or completely get rid of the dependence of crops on natural conditions.

The intelligent greenhouse control system is a remote monitoring and management system configured for the control requirements of the normal and effective operation of the greenhouse. Using sensor technology and relying on the traditional greenhouse production process, the software and hardware system is designed with high reliability, safety and scalability.

The greenhouse monitoring and control system makes full use of the Internet of Things technology and configuration software to remotely obtain the air temperature, humidity, light intensity, soil moisture temperature, carbon dioxide concentration, leaf humidity, dew point temperature and other environmental parameters inside the greenhouse in real time. and video images, through model analysis, remote or automatic control of wet curtain fans, spray drip irrigation, internal and external sunshade, top and side windows, heating and supplementary light and other equipment to ensure that the environment in the greenhouse is more suitable for crop growth; at the same time, the system can also Real-time monitoring information, early warning information, agricultural technology knowledge, etc. are pushed to farmers through information terminals such as mobile phones, PDAs, and computers, so as to realize intensive and networked remote management of greenhouses.

Three, system advantages:

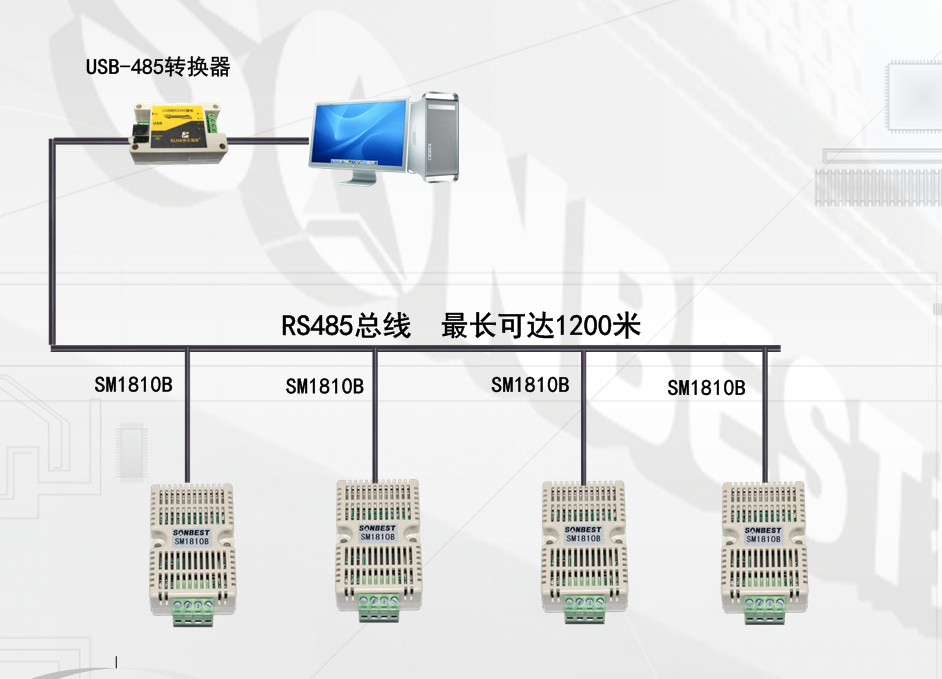

1. The combination of industrial 485 bus, optical fiber intercity network, and standard industrial current signals is used to collect and transmit data to ensure the stability of data transmission, reduce costs as much as possible, and reduce the complexity of on-site construction wiring.

2. The genuine industrial automation configuration software supports the upgrade of local software and remote software, which is convenient for future function expansion.

3. Online, receiving and sending data will not generate communication fees for internal systems.

4. The application is flexible and convenient: as long as the RS-485 signal and the RJ45 signal are passed through the hardware protocol converter, the serial port of the server computer can be directly connected.

5. The network is simple, fast and flexible.

6. For the industrial 485 network, fixed device address management, automatic identification of terminal devices, to ensure the connection and security of the network.

7. In addition to providing standard general functions, functions can also be customized according to the special needs of users.

4. On-site data collection and control functions

The parameter sensors in the greenhouse can collect multi-point real-time dynamic acquisition of the greenhouse environment, and then send it to the single-chip microcomputer for processing through A/D conversion, and drive the execution device to realize the automatic and intelligent adjustment of the greenhouse environment. The display device displays the temperature, humidity, illuminance and other values in the greenhouse in real time, which can display the whole picture of the greenhouse data more clearly.

(1) Temperature and humidity monitoring

The humidity sensor monitors the temperature and humidity of the outdoor air environment of the greenhouse, the temperature and humidity of the indoor air environment, the surface temperature and humidity, the soil temperature and humidity, etc., and can collect, analyze, calculate, control, store, and send the data.

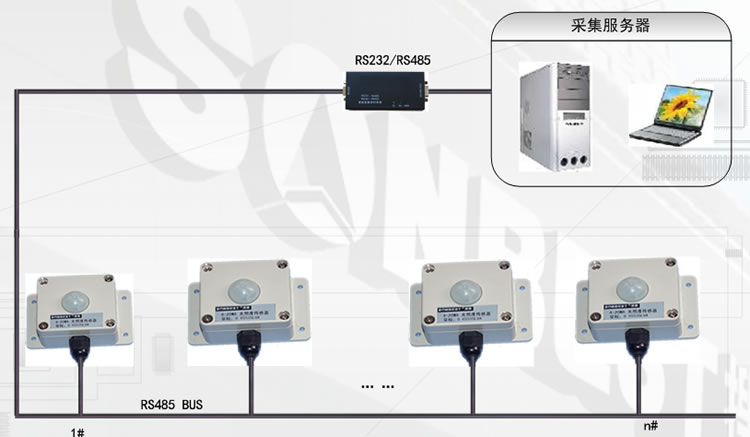

(2) Illumination monitoring

The illuminance sensor monitors and records the intensity of the light in the greenhouse, which can be directly connected to the related equipment such as the supplementary light system, the shading system, etc., and the related equipment is automatically turned on when necessary. The relevant data is transmitted to the user monitoring terminal through wireless transmission technology.

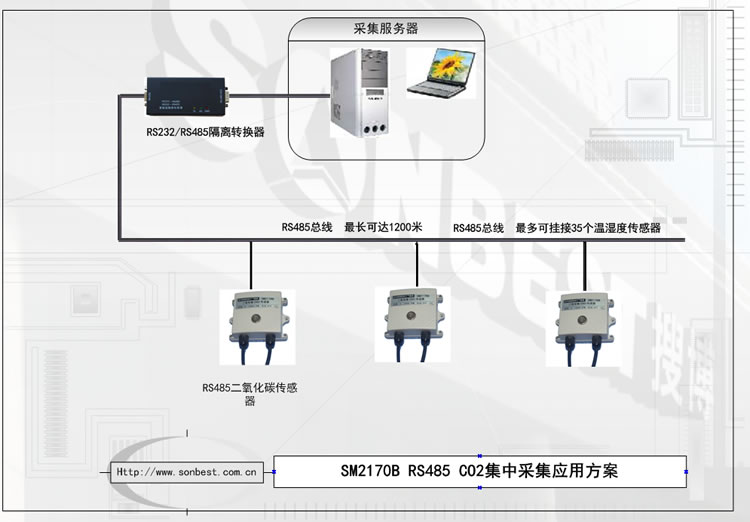

3) CO2, O2 concentration monitoring

A carbon dioxide concentration sensor is deployed in the greenhouse to monitor the carbon dioxide content in the greenhouse in real time. When the concentration exceeds the threshold range set by the system, the relevant data will be transmitted to the user monitoring terminal through wireless transmission technology, and the relevant staff will make corresponding adjustments.

(4) Sub-area detection

The internal control and management of the area can realize environmental technical indicators such as different temperature and humidity, and different gas configurations in each planting area. Users can monitor and query the data of each area through the host computer. It is also possible to perform individual control and overall coordinated control of each block.

(5) Irrigation and spraying and fertilization control

Water irrigation and pesticide spraying use a pipeline system, which can be operated automatically or manually according to the plant growth mode.

(6) Alarm control

Users can set the upper and lower limits of certain parameter indicators. For example, the temperature of the greenhouse should be between 30-15 degrees Celsius. Above or below this temperature range, an alarm message will be generated and displayed on the central control platform of the upper computer and the on-site control node.

(7) Node failure notification

When the on-site control node fails, the manager can be notified in time through the central server platform, mobile phone text messages, and alarm information.

(8) Backup redundancy function

In order to avoid inconvenience caused by equipment failure and abnormality, affecting the growth of crops. The equipment can be extended redundantly. When the equipment fails, the auxiliary equipment will perform 0 switching. So as to achieve continuous trouble-free operation, increase system stability and reliability.

(9) Custom control mode

According to the specific control and monitoring needs of the greenhouse, some corresponding monitoring items and control contents can be customized. This item can monitor and control analog signals, digital signals, switching signals, and frequency signals.

V. Monitoring software data platform

The automatic monitoring software of ecological agriculture intelligent greenhouse collects the field data in the greenhouse, transmits it to the ZigBee node or RS485 node through the sensor data module, and then transmits it to the data platform through wired, wireless, 3G/2G network, and analyzes it according to the relevant settings. Display and further complete the corresponding control.

1. Friendly user login management interface

Provides user access rights, different users provide different operation rights, non-users cannot log in to the system, ensuring system security, simple and user-friendly operation.

2. Real-time\history, curve\report data analysis

The system displays the collected data information to the user in the form of real-time curves, and generates historical reports according to the daily, monthly, quarterly and annual parameter change curves as needed. It is convenient to analyze and improve the operation of the greenhouse, and improve the production efficiency of the greenhouse.

3. Various forms of alarm functions, suitable for different occasions

The staff set the temperature, humidity and other parameter limits according to the specific conditions in the greenhouse. During monitoring, if it is found that the monitoring result exceeds the set threshold, the system will automatically issue an alarm to remind the staff.

4. Remote control

The on-site acquisition equipment transmits the collected data to the central control data platform through wired, wireless and 3G/2G wireless networks. The user can view the real-time data of the greenhouse site from the terminal, and use the remote control function to control the equipment or analog output module through relays. Control operation of greenhouse automation equipment, such as automatic spraying system, automatic ventilation system, automatic watering system.

5. Monitoring terminal

The monitoring terminal realizes the following main functions through the visual and multimedia human-machine interface: ①Comprehensive display and query of the plant growth environment in the greenhouse, including various parameters, light intensity and historical data; ②Send scheduling commands to the monitoring system in the greenhouse , Adjust the operation of the equipment to ensure that the greenhouse is a more suitable environment for plant growth.

Six, control cabinet/main controller/controller

1: The main controller can continuously collect and record the temperature, humidity, wind speed, carbon dioxide, light intensity and other parameters of the monitoring point in real time for 24 hours online, and display and record and store it in real time in various ways such as numbers and images. Monitoring information, monitoring points can be expanded.

2: The data concentrator provides RS485 interface. If there is no wireless monitoring computer or the monitoring computer is damaged or paralyzed, you can use RS485 to connect the computer to export and transfer the data to other computers at any time.

3: The temperature and humidity monitoring software adopts the standard Windows 98/2000/XP full Chinese graphical interface to display and record the data value and curve change of each monitoring point in real time, and count the historical data, larger value, smaller value and average value of each data , cumulative data, etc.

4: The monitoring host can use monitoring software to print data and operation reports at any time at any time.

5: The powerful data processing and communication function of the main controller